110 copper sheet plate is widely known for its architectural applications whereas the familiar green patina appearance is acheived when exposed to the elements copper sheets and plates have excellent hot or cold workability and is ductile when heated.

Copper and brass sheets are hard and brittle.

We offer the most comprehensive processing in the copper and brass industry.

Annealing copper makes it softer and less brittle which allows you to bend it without breaking it.

Make sure that you add some flux to the area to be soldered.

Copper and brass sales a division of thyssenkrupp materials north america is the source in your supply base that provides you with the inventory management expertise and value added processing services necessary to help you compete in today s global market.

By providing high quality service in conjunction with products at competitive prices our warehouse has grown to 100 000 sq.

In this case i m soldering a copper reducer to a piece of copper pipe.

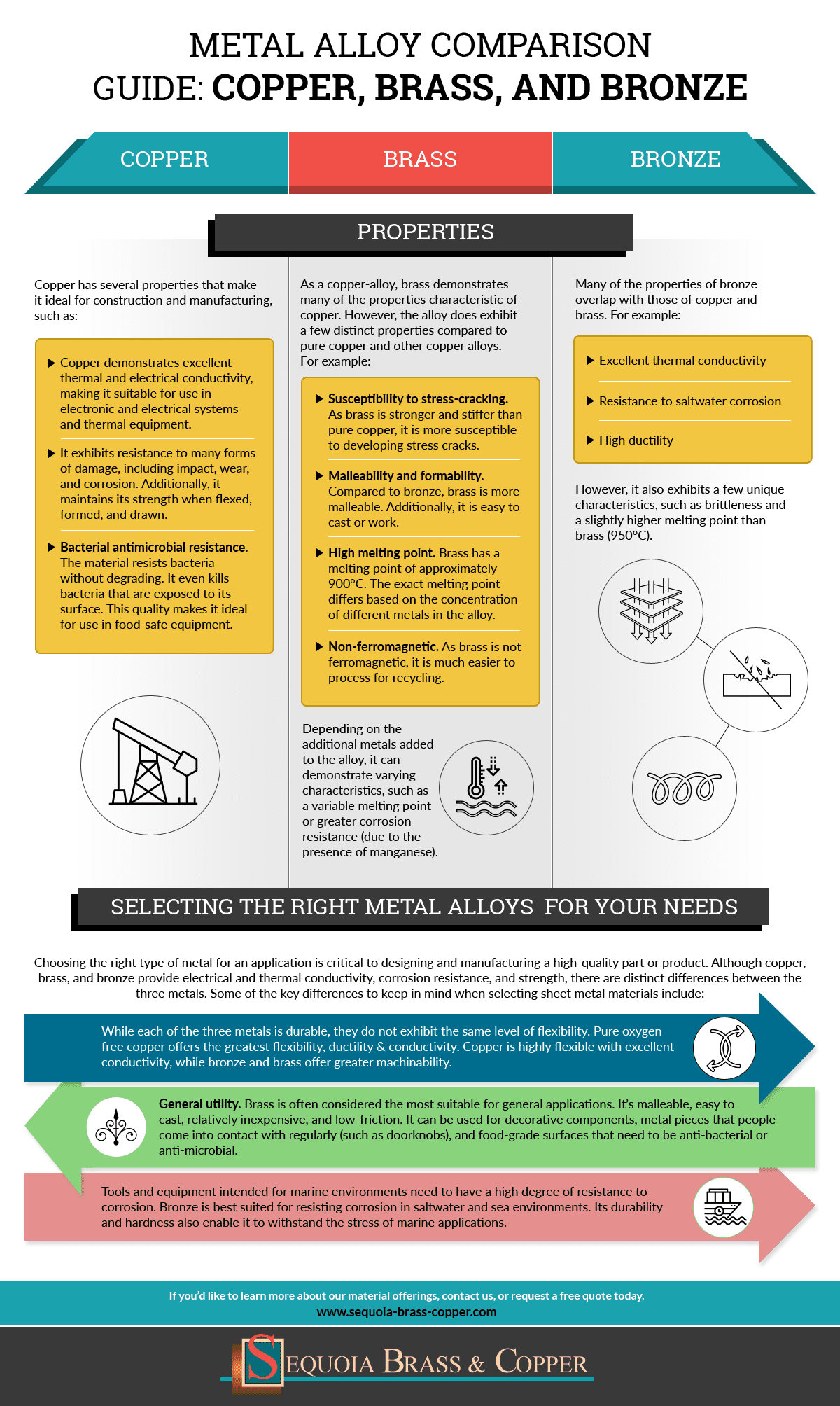

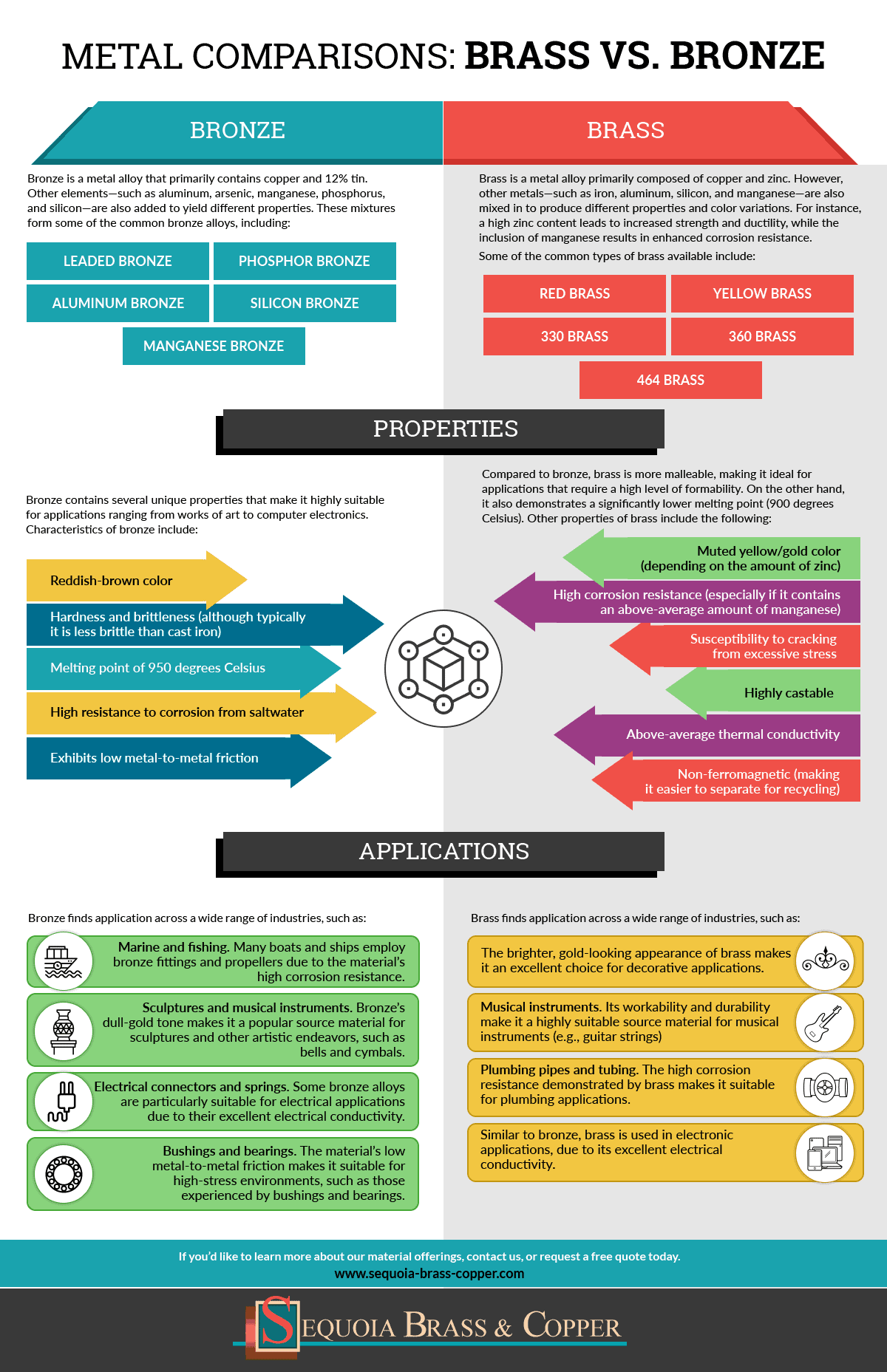

While brass is an alloy of copper and zinc bronze is an alloy consisting mainly of copper combined most often with tin but at times also with other metals.

Copper sheets plates are also noted for their high electrical and thermal conductivity and good corrosion resistance.

You can anneal any grade and.

Place the 2 pieces of copper brass you want to solder on a hard surface.

Other metal sheet resources by sequoia brass copper.

A world class metal distributor and expert in your supply chain.

Sequoia brass copper has been sourcing and cutting metal since 1983 and currently maintains iso 9001 2015 certification.

This includes edge conditioning sawing.

Brass and bronze are metal alloys used extensively in everyday objects.

Coil sheet united states brass copper one of the largest independent direct source suppliers of copper and brass mill products offers you a comprehensive hands on guide to ordering custom or stock mill products.

I use a paste flux which is self cleaning although you should still wipe it with some isopropyl alcohol afterwards.

We started with a small 1 000 sq.

Owing to their properties these two alloys have various uses.

Cbc specialty metals was founded in 1983 to supply brass tubing to the marketplace.

This malleability allows you to hammer and mold the copper into any shape you wish without cracking the metal.

We supply only the highest grade metals that comply with international product standards.

With our comprehensive line of nonferrous metals and alloys wide.

With over 30 years of experience sourcing and buying alloys we have the knowledge and skills to source specialty and hard to find copper alloys for your unique needs.