Put for range of 0 1ppm 0 2ppm and.

Cooling tower water conductivity range.

Warm water and air in cooling towers can become a breeding ground for biological growth.

The necessary precautions include.

On the other hand an increase in range will cause.

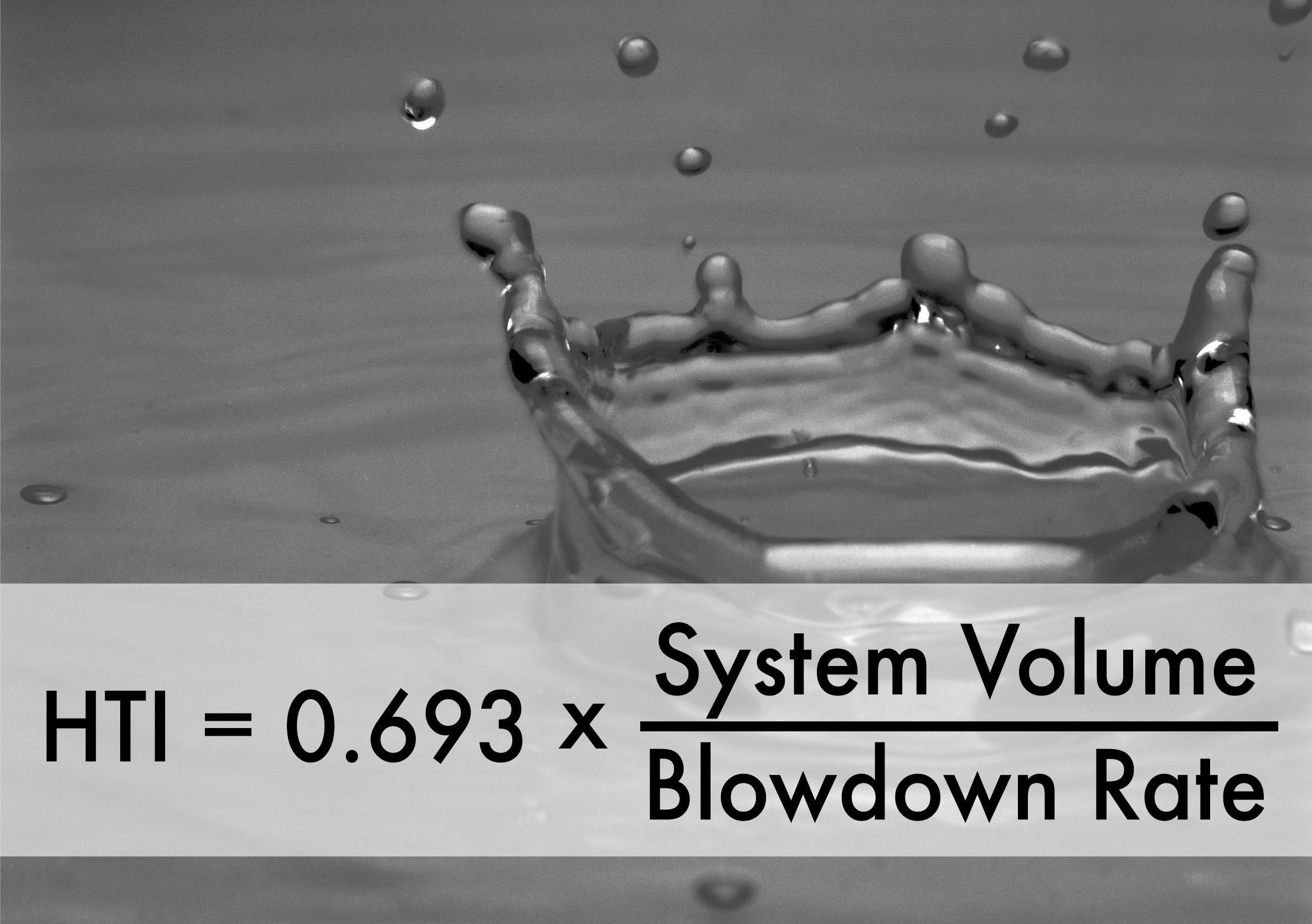

Coc make up water quantity blowdown water quantity the last formula gives you more accurate coc if you have flow measurement facility available for makeup blowdown water in the cooling tower.

Cooling towers are rated in terms of cooling tower approach and cooling tower range where the approach is the difference in temperature between the cooled water temperature and the air wet bulb twb temperature.

Other cooling tower calculations.

Coc conductivity in cooling water conductivity in makeup water.

The range does not represent the cooling tower capability.

Example from below data approach 85 80 5 f.

The primary function of the tower and the method that transfers heat from the cooling tower system to the environment.

If the conductivity of the cooling water exceeds the front panel set point the controller activates a blowdown process.

Coc conductivity of cooling water conductivity of makeup water.

Water leaves a cooling tower system in one of four ways.

The range is the temperature drop across the tower example from below data.

A conductivity controller monitors the electrical conductance of the cooling water.

Limit the duration of the cleaning to one day or at the most two days.

Cooling tower efficiency range range approach x 100.

During blowdown some of the highly conductive water is released and chemicals are added to the tower water.

The thermal efficiency and longevity of the cooling tower and equipment depend on the proper management of recirculated water.

Rather the range is based on the cooling water circulation flowrate l in and the sum of the heat loads taken from the heat exchangers in the process unit q and it is not related to the size or capability of the cooling tower.