We can configure our systems with special output uv led illumination panels for the highest coating inspection performance with long life and low energy costs.

Conformal coating uv light inspection.

Great for conformal coating inspection.

Fits model sz 45 stz 45 lx 100 vzm 200 vip 50.

With a wide operating temperature range and excellent electrical properties uvcl uv cure conformal coating is suitable for a wide variety of applications.

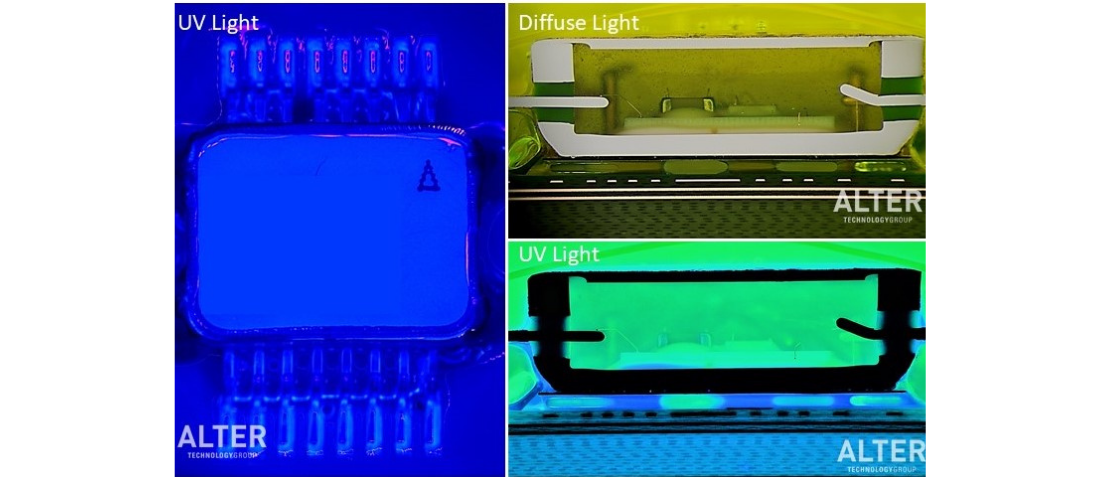

Uv blue tracer additive is incorporated within the formulation of the coating and glows bright fluorescent blue under uv blacklight.

The conformal coating uv inspection lamp is a 300cm illuminated rectangular glass lens magnifier.

This will provide the highest quality results for the conformal coating process.

Highlighting particulate micro contamination during cleanroom validation and surface cleanliness checks before applying coatings.

The inspection lamp has a magnification of 1 75x.

Electrolube imc may be used to clean coating equipment following use and prevent blockages.

360 dual led ring light design.

Conformal coating uv inspection booths our manual inspection booths can provide the perfect environment for pc board conformal coating inspection.

Micro contamination detection uv blacklight inspection lamps are used for.

It is suitable for inspecting conformal coatings.

Built in light intensity adjustment.

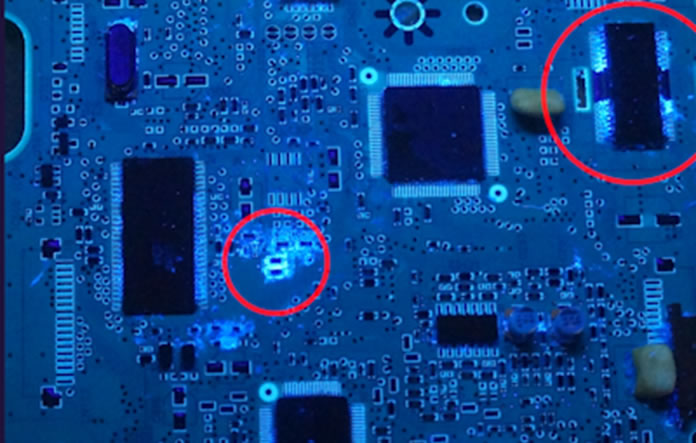

Uv light pcb inspection for conformal coating validation uv a blacklights are used for inspection of conformal coatings on printed circuit boards pcbs to check for uniform coverage.

The objective is to determine if all the surfaces and electrical parts are adequately and conformally coated.

A uv trace is included to aid inspection and ensure the best coverage is achieved.

Since coatings are transparent units must be viewed under black light in order to verify coverage and non coverage.

Less reflection on specular surfaces solder metal parts etc fits all stereo zoom microscope and video inspection systems.

First point is to provide the perfect conditions where an operator can easily inspect conformal coated circuit boards without fatigue to body or eyes.

Uv inspection conformal coatings used by electronic manufacturers contain uv indicators for the purpose of inspection.

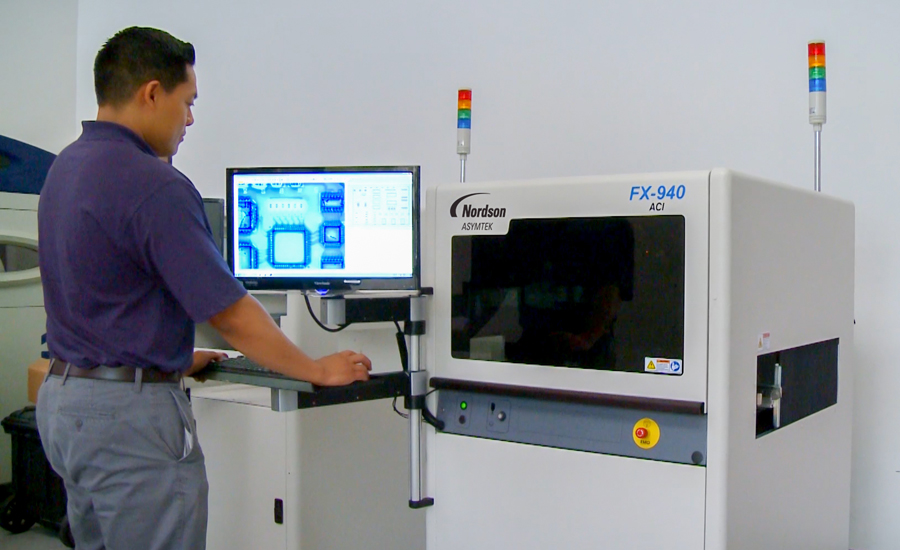

Nordson yestech s line of systems makes conformal coat inspection simple and convenient by automating the inspection process for quality consistency and thickness of coatings under uv lighting with the use of proprietary inspection algorithms.

Since coatings are transparent units must be viewed under black light in order to verify coverage and non coverage.

The inspector typically works within a suitable space such as an inspection booth.

Additional inspection criteria for conformal coatings visual inspection of coating coverage employs an ultraviolet uv lamp sufficiently equipped to effectively compare fluorescent areas to uncoated portions.