Without regular preventive maintenance of freezer floors damages can lead to dangerous conditions for the traffic that goes into these areas.

Concrete freezer floor replacement.

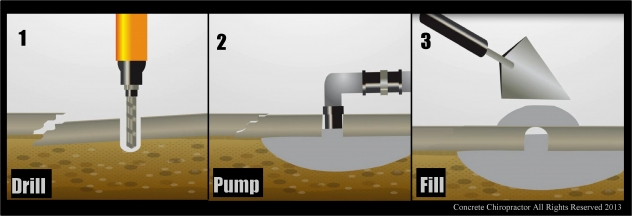

There are a lot of elements involved in preparing and pouring a concrete freezer floor.

Waste heat sources can be via an ammonia compressor air compressor or even through solar collection.

It can be used as a corrective measure to repair a heaved floor slab.

Can be poured into holes from 3 4 to 4 deep in one application.

Spectrum industrial flooring can repair failed flooring and concrete in freezers and cold storage.

Flowpatch sub zero is ideal for concrete repair in cold rooms freezers sub zeros or other food storage areas.

28 c in just a few hours.

The unique microdoweling polyurethanes in concrete mender will cure at temperatures well below 20 degrees f.

Safety yellow line marking with concrete mender yellow.

Cold storage freezers walk in cooler floor repair.

Sets in two hours even in sub zero conditions for repairs without shutting off refrigeration.

Spectrum industrial flooring can remove failed areas and repair them for a quick return to service.

Repair is only an option if the heat tapes can be placed inside 1 galvanized conduits located in the sealed end of failed air ducts.

When things go wrong repairing a damaged freezer floor is just as challenging.

The unique microdoweling polyurethanes in concrete mender will cure at temperatures well below 20 degrees f.

Ideal for use in walk in freezers and coolers.

For everything about concrete curing in freezers powerblanket is here to help.

Kwik bond is designed for concrete floor repair on frozen surfaces such as freezers coolers and holding boxes.

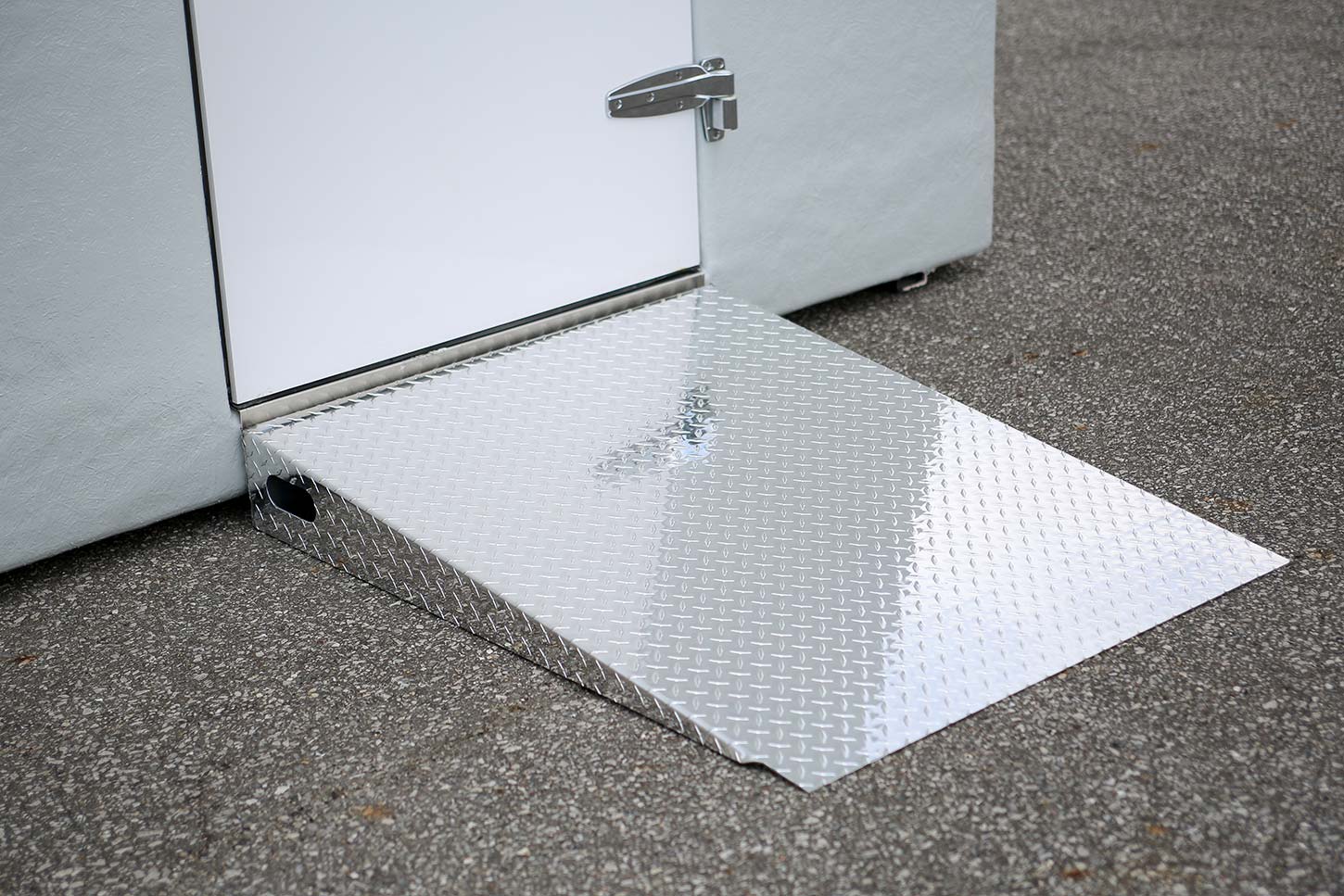

Particularly in door entrances or in freeze thaw conditions.

Ideal for filling high traffic holes or deep repairs at sub zero temperatures.

Delta chemicals formulated a no odor freezer floor repair np128 20 minute set time 11 000 p s i.

Down to 40 degrees.

119 per kit buy 2 get 1 free.

Freezer patch odor free.

Concrete repair for freezer and cold storage warehouse floors.

We have the ability to utilize various systems that are specifically designed for these difficult environments.

Glycol tubing under floor heat one of the most economical methods of applying heat to a freezer floor is to pump glycol through tubing that has been heated from a waste heat source.

Recommended for cold storage areas freezers or general outdoor patching in the winter.

Over time concrete can become spalled or fail completely.

Our products are extremely fast curing concrete floor repair for very low temperatures down to 60 degrees fahrenheit.

28 c in just a few hours.

Walk in freezer floor repair is required any time your walk in freezer concrete surface shows signs of cracks spalls chipping or pitting.

Taking extra precautions before during and after you pour will ensure your slab is built to last.

Epoxy floor patch sets in two hours even in freezers as cold as 20 degrees f.

Withstands heavy traffic without cracking.

If your business is refrigerated warehousing or grocery distribution roadware 10 minute concrete mender is the premier concrete repair product for keeping your floors in top condition.