To satisfy the high performance and low weight constraints high strength carbon fiber composites are the materials of choice for flywheel construction.

Concrete flywheel energy storage.

Swiss startup energy vault has devised an energy storage system that uses blocks of concrete weighing 35 tons a piece.

Uninterrupted power supply an uninterrupted power supply can be maintained as flywheels energy storage systems have faster discharge rates and it doesn t experience the load unlike battery storage systems.

According to cal ohsa the flywheel was in a concrete vault used to test an energy storage system.

The future of flywheel energy storage.

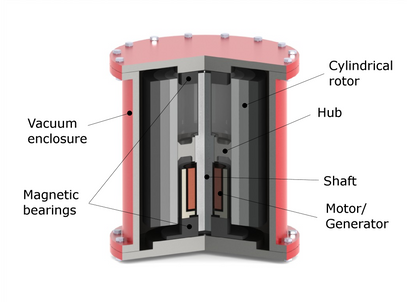

Modern flywheel energy storage systems generally take the form of a cylinder known as a rotor enclosed in a sealed vacuum chamber to eliminate air friction.

Velocity can exceed 10 000 revolutions per minute rpm with.

It uses off the shelf technology but uses a new process to make the concrete.

Flywheel energy storage fes works by accelerating a rotor to a very high speed and maintaining the energy in the system as rotational energy when energy is extracted from the system the flywheel s rotational speed is reduced as a consequence of the principle of conservation of energy.

Energiestro s flywheel design has the potential to be a valuable addition to the storage options for variable renewables said voltalia which will install the 10kw 10kwh test system at a site.

Just before the explosion it was spinning at 6 000 rotations per minute.

Adding energy to the system correspondingly results in an increase in the speed of the flywheel.

London business wire technavio has been monitoring the flywheel energy storage market and it is poised to grow by 527 88 mw during 2020 2024 progressing at a cagr of over 8 during the.

A concrete based flywheel energy storage system will get its first deployment after global wind and solar developer voltalia signed up for a prototype.

The energy stored in the flywheel can be retrieved to supply power for electrical drive machinery.

In june 2011 the beacon power corporation completed the company s first flywheel energy storage plant in stephentown new york at a cost of 60m.

The plant utilises 200 flywheels spinning at a maximum speed of 16000 rpm to store excess energy and help regulate the supply to the local grid.

If you have a 400kg flywheel yes i m ignoring second moments defined by flywheel shape for now doing 500rpm 51 rads sec you get about 1067kj of stored energy if you take a 4kg flywheel and spin it at 5000rpm 517 rads sec.

Flywheel energy storage in action.

Composite flywheels are currently being developed for energy storage.

2 the rotor is often made from new materials such as carbon or glass fibers or kevlar which withstand very high speeds better than traditional metals.